Finalist

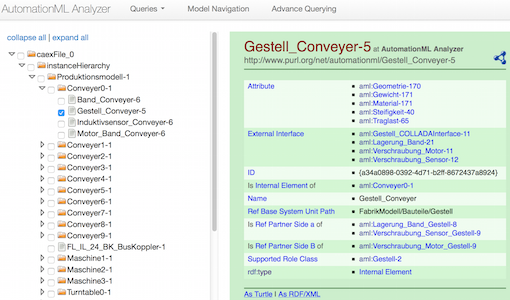

AutomationML Analyzer: Interface for browsing integrated mechatronic engineering models.

The AutomationML Analyzer (http://data.ifs.tuwien.ac.at/aml/analyzer) enables efficient integration, browsing, querying, and analysis of diverse engineering models represented in the AutomationML data exchange format.

This tool aims to support the engineering phase of complex mechatronic systems (e.g., power plants), an important subset of the emerging Cyber-Physical Systems. This phase is characterized by a large set of stakeholders, coming from different engineering disciplines that have to collaborate to satisfy project requirements and time frames. To ensure optimal project management as well as to avoid risks of inconsistencies between engineering models created by different disciplines, support is needed for integrating and subsequently analyzing diverse engineering data.

Integration of data from different engineering disciplines is hampered by the use of isolated and heterogeneous vocabularies and sets of engineering tools with diverging data models and representation formats, which were developed within the individual engineering disciplines. The AutomationML standard aims to support data exchange by offering an engineering discipline independent language for encoding engineering data. While AutomationML ensures data exchange through a uniform data encoding, solutions are still needed for connecting engineering files, browsing along the main connections between these files and allowing project level (and not just discipline specific) analysis of engineering data.

Linked Data technologies are highly suitable for integrating heterogeneous, and distributed datasets that have links between them. It supports not just integration, but also mechanisms for sense making of this data in terms of browser-based navigation and formal, reasoning-enabled querying. The AutomationML Analyzer adopts an innovative approach by applying these key features of Linked Data technologies in the complex domain of industrial engineering. Its main functionalities include:

a) integrating the engineering data from different disciplines and tools;

b) flexible and intuitive browsing through the entire automation system model and data including links between the fragments of system models defined within different disciplines;

c) advanced engineering data analysis and consistency checking over heterogeneous data coming from different disciplines and tools, which are typically isolated. This is enabled by querying and reasoning over the integrated data to automatically perform checks such as “Whether a PLC variable is defined for each I/O interface in the electrical view”. Previously such checks would require costly, manual analysis of various, not-interlinked engineering data sets by domain experts.

The AutomationML Analyzer embraces open standards (AutomationML, RDF(S)) and relies on a mature technical solution. AutomationML data is automatically transformed to RDF(s) format and enriched through the extraction of an ontology from AutomationML files as well as mechanisms that make implicit cross-disciplinary links explicit. These explicit links are a key to enable project wide data navigation and querying. The RDF(S) data is stored on a Sesame server. A Linked Data interface (generated with Pubby) allows project wide data navigation. A SPARQL end-point enables querying project wide data to perform engineering level consistency checks as well as project management level analysis.

Since the end-users of this tool are engineers or project managers, ensuring a high degree of comprehensibility for the users is an important goal. To that end, the AutomationML Analyzer hides the complexity of Linked Data technologies by (1) enabling one-click file upload and performing data enrichment and linking automatically; (2) allowing flexible web-based browsing and navigation through the integrated engineering data representing the whole automation; (3) providing a set of pre-defined queries that serve typical cross-disciplinary analytics tasks to avoid the need for writing SPARQL queries.

Standardized under IEC 62714, AutomationML recently gained a lot of interest from the industrial stakeholders, especially in relation with the Industrie4.0 movement. The AutomationML Analyzer will therefore leverage on the current industry-wide adoption of AutomationML to introduce the benefits of Linked Data technologies into the engineering domain. As such a network effect in technology adoption can be expected. Additionally, while one of the strengths of the tool lies is providing a global view on engineering models from different disciplines, it can also be used to browse and analyze models created by a certain engineering discipline. The adoption of the tool in domains such as mechanical engineering, electrical engineering, communication system engineering, PLC programming is straightforward and can be expected. The approach of linking and visualizing interlinked models, on which the AutomationML Analyzer relies, is generally applicable to other model-driven approaches as well. For example, model driven engineering projects are likely to benefit from the interlinked presentation of ECore models, as we are investigating in an ongoing collaboration.